| View previous topic :: View next topic |

| Author |

Message |

solentlife

Extreme 3D

Joined: 30 Dec 2010

Posts: 932

Location: Latvia / UK

|

Posted: Sun Jan 02, 2011 6:26 pm Posted: Sun Jan 02, 2011 6:26 pm

Post subject: Main shafts, feathering shafts, flybars, tail booms .. Post subject: Main shafts, feathering shafts, flybars, tail booms .. |

|

|

So how do you straighten your shafts or tail booms ?

Do you just replace with new and discard old ?

Me ?

Tail booms if metal tube are easy. To remove dents and straighten - you need a long metal rod with a round tapered ball end to straighten the boom and will also remove most of the dents / creases.

By holding the boom carefully - NOT in a vice as that makes flats - but by hand. You carefully tap the rod down the boom forcing out the dents and creases as it goes. This is usually enough to also straighten the tube. Standard Trex booms are between 10 and 11mm ID .. so I use a masonry long drill first at 10mm and then a wood dowel. You can if careful 'lever' stubborn dents with the drill. Best of course is a rod purpose OD to fit the tube.

Second method to remove dents / creases from booms is the old Trumpet / Trombone repair shop trick of the connected steel balls. They form a snake like instrument that can be pulled through a tube to force dents out ...

OK - now shafts ....

What you need is a variable speed battery drill. You insert shaft in the drill and slowly spin it up ... you will see the wobble due to the bend. Very rare is the bend compound on a main shaft ... usually on Trex it is at the weak point, a groove in the shaft designed in so you can remove shaft even when damaged from bearings etc. So rotate the shaft till at comfortable position and then a pair of plumbers grips to carefully ease the shaft straight again ... run up and see the amount of wobble. Bending back in small amounts till you have best possible ... Do not try to bend back in one go - a) you may weaken the shaft, b) overdo it spoiling any further use of the shaft.

Unfortunately with feathering shafts - there is no designed in weak point and often the bend is twofold ... so extreme care in placing in drill is needed and the bending back exercise. Second is the tendency to deform the end screw threaded part, so insert a screw to protect that.

Flybars are difficult as they are thin and too long for drill. Second they also usually have a compound bend ... so these I bend by hand ...

All shafts can be tested for straightness by rolling on a plain sheet of glass such as a mirror.

All shafts so repaqired go in my "recycled" bag - as emergency use only when I have no new ones left and waiting postman.

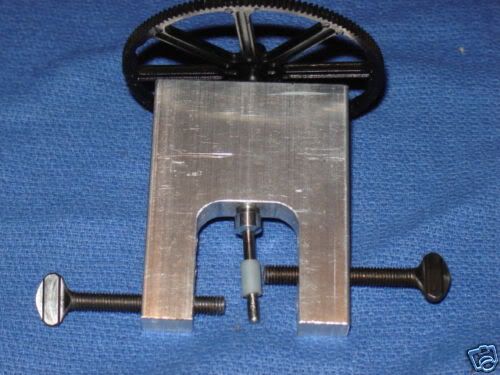

I am waiting for a machine being made for me by a metal-fabricator pal of mine ... based on a drill chuck fitted to similar to this :

....... so how do you do it ? |

|

| Back to top |

|

|

admiral

Extreme 3D

Joined: 20 Mar 2009

Posts: 1101

Location: Brisbane, Australia

|

Posted: Sun Jan 02, 2011 7:42 pm Posted: Sun Jan 02, 2011 7:42 pm

Post subject: Post subject: |

|

|

Hi solentlife,

I straighten my shafts useing a piece of hardwood and an electric drill, I put the hardwood in the vise and drill a hole in it which is a tight fit for the shaft then with the shaft in the chuck of the drill force it into the drilled hole and ream it backwards and forwards a couple of time 9 times out of 10 it will straighten the shaft in smaller helicopters, I would not recommend doing it more than once or twice per shaft as it is likely that they will fail in flight eventually.

Tail booms I have a cleaning rod from a rifle that I force through SR and Twister Gold booms does a great job, again only once or twice or the part may fail in flight. |

|

| Back to top |

|

|

solentlife

Extreme 3D

Joined: 30 Dec 2010

Posts: 932

Location: Latvia / UK

|

Posted: Sun Jan 02, 2011 8:40 pm Posted: Sun Jan 02, 2011 8:40 pm

Post subject: Post subject: |

|

|

mmmmm interesting ....

I've heard of one guy who puts shaft in a drill ... has a piece of hardwood in other hand ... forces shaft against bench edge and presses with wood while running the drill ........ he reckons it works. Have to say I have difficulty trying to picture how ?

With GRP / CF booms as were many helis in 80's .... and expensive. Many of us worked out ways to repair those.

Remove boom and belts etc. so that boom is completely on it's own.

Mix up medium speed epoxy ... 1hr stuff is fine, longer if you don't mind the wait. 5min is possible but you'd need to work fast ...

With small flat wood piece such as an 'ice-cream' freebie - you smooth the epoxy onto the boom over the splits ... CF booms rarely break - they tend to splinter along the fibres .. Once a nice film is applied ... take a hairdrier and waft it over the epoxy which will thin and run into the splits ... (this is why slower epoxy is best as heat speeds up setting ! and we need it to stay fluid for next step ..... )

Now take clear packing tape and wrap tightly around the boom in a spiral - which forces the boom into it's round shape again, creates a smooth finish to the epoxy ... (you can use non-sticking polythene but needs sticking at ends to make sure it stays bound while epoxy sets).

When epoxy is set and removal of tape will not let boom fail - you can remove the tape. You will now have a boom that will be strong and useable again.

We were able to do this quite a few times with booms in those days before having to buy new.

It is worth viewing down the interior of the boom to ensure no shreds are proud and would tear the belt ... a long masonry drill passed down through sorts that. |

|

| Back to top |

|

|

pjdog

Extreme 3D

Joined: 12 Jan 2010

Posts: 2073

Location: Hudson, Florida, USA

|

Posted: Mon Jan 03, 2011 1:54 am Posted: Mon Jan 03, 2011 1:54 am

Post subject: Post subject: |

|

|

Back in the old days (1970's) I saw a guy (Bob Pinto In Indianapolis) put a nitro 40 size helicopter main shaft and using a electric drill make the shaft straight as an arrow.

I just get a new one.

Jack. |

|

| Back to top |

|

|

solentlife

Extreme 3D

Joined: 30 Dec 2010

Posts: 932

Location: Latvia / UK

|

Posted: Mon Jan 03, 2011 2:01 am Posted: Mon Jan 03, 2011 2:01 am

Post subject: Post subject: |

|

|

| pjdog wrote: | Back in the old days (1970's) I saw a guy (Bob Pinto In Indianapolis) put a nitro 40 size helicopter main shaft and using a electric drill make the shaft straight as an arrow.

I just get a new one.

Jack. |

Sorry - but what did he do to the shaft when it was in the drill ? |

|

| Back to top |

|

|

silhouette015

Site Admin

Joined: 06 Jul 2007

Posts: 581

Location: Thailand

|

Posted: Fri Jan 14, 2011 3:02 pm Posted: Fri Jan 14, 2011 3:02 pm

Post subject: Post subject: |

|

|

|

kmk's tail boom repair technique has been moved here. |

|

| Back to top |

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

|

|